The drive system is the muscle of industrial automation.

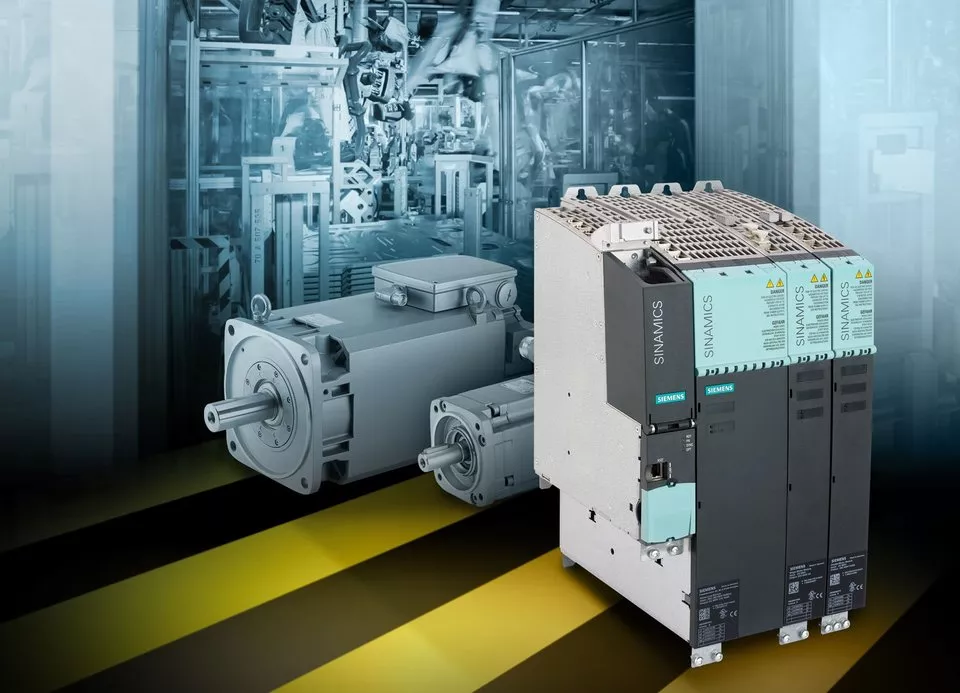

For complex, high-performance machinery, standard, fixed-function drives often fall short. The Siemens SINAMICS S120 revolutionizes this space. It is a modular, high-end drive designed specifically for applications demanding extreme precision, superior scalability, and coordinated multi-axis movement. Instead of a rigid, pre-packaged solution, the S120 empowers engineers. They can configure the exact components needed, ensuring optimal performance without unnecessary hardware costs. This “building-block” approach is a game-changer in modern factory automation.

The Modular Architecture: Simplifying Complexity

The S120’s core strength lies in its modular structure. The system consists of specialized components connected via DRIVE-CLiQ, a proprietary, standardized digital interface. DRIVE-CLiQ is more than just a bus; it simplifies integration, dramatically reduces the variety of required spare parts, and cuts inventory costs. Crucially, it enables real-time communication between all modules. Each component includes an electronic type plate for automatic identification through DRIVE-CLiQ. Therefore, this feature speeds up commissioning and completely eliminates tedious manual setup errors.

The S120 architecture comprises four main component types:

- Control Units (CU): The central ‘brain’ handling motion control, integrated safety functions, and crucial communication interfaces. Models like the CU320, CU310, and CU305 support Vector, Servo, and V/f control modes.

- Line Modules (LM): These convert incoming AC supply into DC link voltage. Engineers choose between non-regenerative and regenerative versions, which can recover braking energy.

- Motor Modules (MM): These are the inverters powering the electric motors. They come in convenient single-axis or double-axis configurations.

- Auxiliary Modules: This category includes essential add-ons such as brake resistors, filter modules for EMI suppression, and fan units for effective cooling.

Moreover, these modules offer incredible flexibility in machine design. They are available in three different physical formats: Booksize, Blocksize, and Chassis. Thanks to the power of DRIVE-CLiQ, all these formats can be mixed and matched.

Key Benefits Driving Efficiency and Performance

The S120 system delivers quantifiable advantages that impact both machine performance and operating expenses.

- Scalability: A user can initiate a project with a small, single-axis system and easily expand it to a vast multi-axis application. This prevents the need for complete system redesigns as production grows.

- Central DC Bus Sharing: Multiple Motor Modules connect to and share a single DC power source. As a result, this design optimizes energy use and improves overall efficiency.

- Regenerative Capability: Regenerative Line Modules are a significant feature. They feed braking energy—which would otherwise be wasted as heat—back into the power supply. This functionality substantially reduces long-term operating costs.

- Multi-Mode Operation: The system supports Vector, Servo, and V/f control modes. This versatility covers everything from high-precision, cyclic motion (like in robotics) to continuous, speed-regulated processes.

- Integrated Intelligence: The electronic type plates and automatic detection via DRIVE-CLiQ minimize setup errors. This reduces machine downtime and accelerates the path to operation.

Industry Adoption: Applications in High-Demand Sectors

The flexibility and high dynamic response of the SINAMICS S120 make it indispensable across diverse industrial automation sectors.

Packaging: This sector requires tight synchronization for high-speed filling, precise labeling, and accurate cutting. The S120’s Servo mode ensures exact motion profiles.

Robotics: For complex articulated and gantry systems, the S120 provides the essential multi-axis control and coordination.

Automotive: Applications include robotic assembly, synchronized conveyors, and detailed automated inspection stations.

Printing & Converting: Precision roll handling is critical for consistent print quality and tension control in web processes.

Metals & Heavy Industry: The system handles demanding applications like rolling mills and presses that require high-load capabilities and robust control.

In addition, the S120 is frequently used in renewable energy systems, specialized plastic manufacturing machinery, and high-accuracy test benches.

Experience, Authority, and Support: The Lifecycle Advantage

From a support and maintenance perspective, the Siemens ecosystem enhances the S120’s value. The system integrates seamlessly with the Siemens Total Integrated Automation (TIA) Portal and the STARTER software. Therefore, this provides streamlined parameterization, consistent data management, and secure project archiving. This integration is a key component of Siemens’ authority in the control systems market.

PLC Pioneer’s Commentary: As an automation professional, I have witnessed the impact of the S120’s seamless integration firsthand. The ability to manage the drive system directly from the TIA Portal alongside the PLC and HMI is a massive time-saver for engineers. When a module swap is necessary, the DRIVE-CLiQ auto-detection drastically reduces mean time to repair (MTTR). The consistent, long-term availability of spare parts from Siemens further solidifies the S120 as a reliable long-term investment, justifying its slightly higher initial cost compared to entry-level alternatives.

We encourage you to learn more about comprehensive system integration and specialized S120 applications by visiting the resources provided by PLC Pioneer Limited.

FAQs: Insights from an Automation Expert

- Q1: What is the biggest difference in commissioning between the S120 and a standard VFD (Variable Frequency Drive)?

- The primary difference is the automatic configuration. Standard VFDs require manual parameter entry for motor data, limits, and fieldbus addresses. In contrast, the S120’s electronic type plates and DRIVE-CLiQ automatically detect the connected motor, Motor Module, and other components. An experienced engineer can save hours or even days on a large multi-axis machine simply because the system handles the physical component mapping automatically, reducing human error risk.

- Q2: How does the regenerative capability really affect my long-term costs?

- For machines with high cyclic operation—like large cranes, stamping presses, or test benches that frequently accelerate and decelerate—a significant amount of energy is generated during braking. A non-regenerative drive converts this energy into heat via a braking resistor, which is a total waste. The S120 regenerative Line Module pushes this clean energy back onto the factory power grid. Depending on local energy costs and the application’s duty cycle, this feature often translates to a tangible reduction in the monthly power bill, sometimes enough to justify the higher cost of the regenerative Line Module within a few years.

- Q3: Is the S120 necessary for a simple conveyor belt?

- No, it is generally overkill for a simple, single-motor conveyor belt operating at a constant speed. The S120 is the premier choice for complex requirements: high-accuracy positioning (Servo control), coordinated movement of multiple motors (electronic gearing or camming), or applications needing the shared DC bus for energy efficiency. For a basic start/stop conveyor, a simple SINAMICS G-series drive is typically the more cost-effective solution.

Further Reading & Solutions

For deeper technical specifications, specialized application notes, and to explore customized S120 solutions for your facility, please click here: PLC Pioneer Limited.