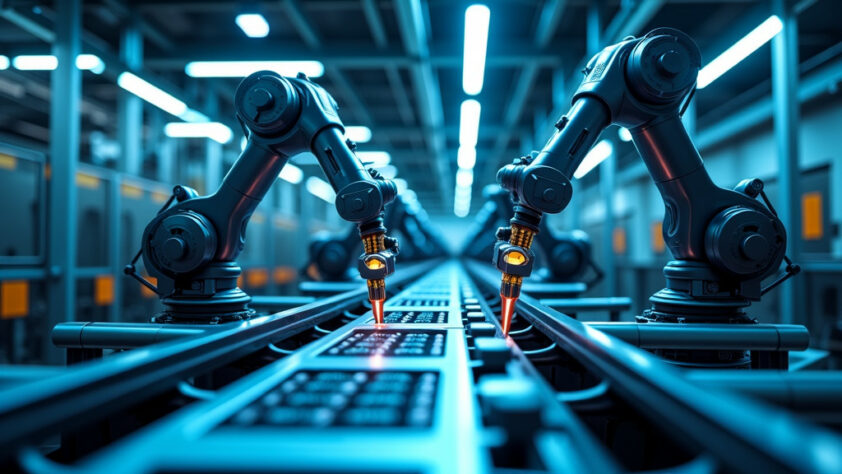

Industry News: Advancing Predictive Maintenance with High-Fidelity Vibration Monitoring

In today’s competitive industrial landscape, unplanned downtime is a primary driver of profit loss. A recent 2024 industry report by McKinsey found that asset failures can cost process industries up to $50 million annually. The shift from reactive to predictive maintenance is no longer a luxury but a necessity for operational excellence.

The Critical Role of Vibration Analysis

Vibration monitoring serves as the frontline defense against machine failure. By analyzing vibration signatures, engineers can detect imbalances, misalignments, and bearing wear long before a total breakdown occurs. Studies show that over 45% of rotating machinery failures are preceded by identifiable vibration trends, making this a cornerstone of any modern industrial automation strategy.

Deep Dive: The 3300 NSv Proximity Probe System

The 3300 NSv system is engineered for precision and resilience. Its key specifications set a new benchmark for reliability:

- Measurement Accuracy: ±1% of full scale, ensuring data integrity for critical assets.

- Temperature Resilience: Operates reliably in environments from -40°C to 120°C (-40°F to 248°F).

- Seamless Integration: Provides a standardized 4-20 mA output and digital protocols for direct connection to major PLC and DCS platforms from Siemens, Rockwell Automation, and Emerson.

Quantifiable Benefits in Real-World Applications

The practical value of the 3300 NSv is proven across numerous sectors. In power generation, a leading plant reported a 30% reduction in maintenance costs within the first year of deployment. In oil and gas, continuous monitoring of centrifugal compressors has helped extend mean time between failures (MTBF) by over 4,000 operating hours.

Expert Commentary: The Data-Driven Future

“We are moving beyond simple monitoring towards intelligent diagnostics,” says Dr. Anna Reid, a senior reliability engineer. “Systems like the 3300 NSv are the foundation. The next step is leveraging this high-fidelity data with AI to not just alert you to a problem, but to diagnose the root cause with over 95% confidence, transforming maintenance from a cost center into a strategic advantage.”

Case Study: Preventing a Multi-Million Dollar Outage

Scenario: A combined-cycle power plant in Texas integrated 3300 NSv probes on its GE 7HA.02 gas turbine.

Action: The system detected a subtle, yet growing, shaft vibration anomaly of 2.1 mils pp, exceeding the normal baseline of 0.8 mils. This triggered an automated alert.

Result: The maintenance team scheduled a planned outage during a low-demand period. Inspection revealed an early-stage blade fouling issue. The total cost of the planned repair was $120,000. The plant management estimated that a forced outage would have resulted in over $550,000 in lost generation and emergency repairs, showcasing a clear and substantial ROI.

Check below popular items for more information in PLC-Pioneer.