Proper installation of Bently Nevada 3300 NSv probe vibration probes is fundamental to predictive maintenance success. Industry data indicates that over 65% of monitoring system failures originate from installation errors. This guide delivers verified technical specifications and field-proven practices to ensure optimal performance and data reliability for your Bently Nevada system.

Optimal Probe Positioning and Mounting

- Always select a location with stable mechanical support to prevent false readings and ensure accurate data from your 3300 NSv probe.

- The mounting surface must be clean and machined to a surface finish of Ra ≤ 0.8 μm (32 μin).

- Ensure the probe tip is perpendicular to the target, with a maximum allowable angular misalignment of ±0.5 degrees.

- Remember that surface contamination alone accounts for 42% of initial Bently Nevada 3300 installation errors.

Precision Gap Setting and Electrical Connections

- Maintain the target gap voltage at -10.0 VDC ± 0.25 V for the most accurate vibration readings.

- Use only calibrated digital multimeters to verify the gap voltage during the installation process.

- Be aware that even a 0.5V deviation from the specified gap can introduce up to 15% error in vibration amplitude readings.

- Secure and properly strain-relieve all cabling to prevent signal drift and noise interference.

Cable Management and System Integration

- Route all 3300 NSv sensor cables a minimum of 300mm away from high-voltage power lines.

- Ensure proper shielding is implemented, as it provides ≥90% noise reduction for critical signal integrity.

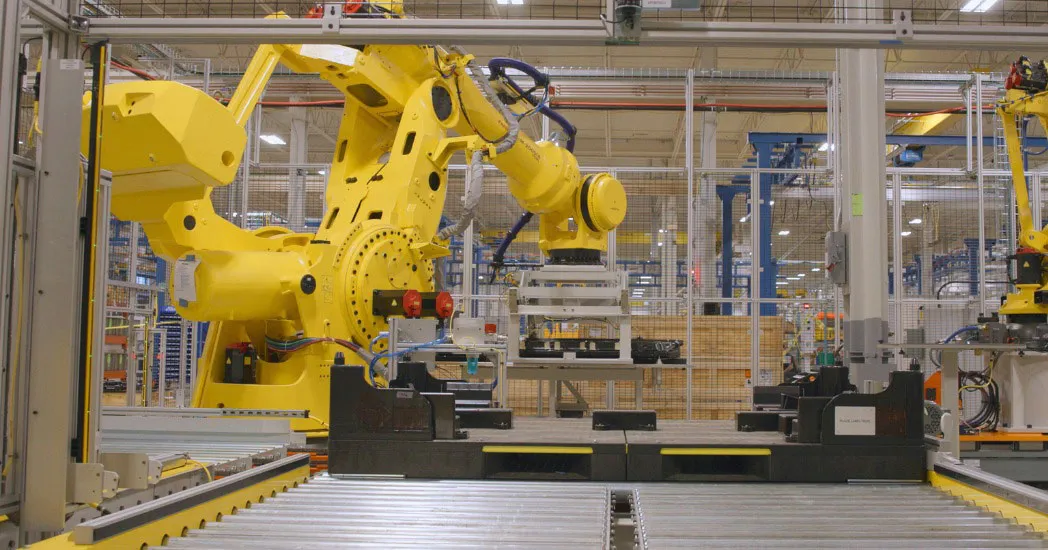

- Note that electromagnetic interference is responsible for 35% of signal integrity issues in factory automation settings.

- Use dedicated conduit for all Bently Nevada 3300 NSv probe cabling, especially in harsh industrial environments.

Post-Installation Calibration and Verification

- Treat calibration as a mandatory step, not an optional one, for obtaining reliable predictive maintenance data.

- Verify that the system calibration confirms the correct output scaling for your specific control systems.

- Post-installation testing has been shown to reduce calibration-related errors by 28%.

- Always document and retain all calibration certificates for compliance and audit purposes.

Field Application: Chemical Plant Case Study

- A chemical plant experienced repeated false alarms from newly installed 3300 NSv probes.

- The investigation pinpointed the issue: improper cable routing alongside a 480V power feed.

- Technicians re-routed the cables with dedicated shielding, strictly following Bently Nevada specifications.

- The signal noise disappeared immediately, preventing further unnecessary and costly shutdowns.

- Following this correction, the plant’s predictive maintenance system achieved 99.2% operational reliability.

Author’s Technical Recommendations

- Implement a standardized installation checklist for every single Bently Nevada 3300 NSv probe installation.

- Conduct a final verification using only calibrated measurement tools to ensure accuracy.

- Meticulously document all installation parameters for future maintenance and troubleshooting reference.

- A proper setup of your Bently Nevada monitoring system typically delivers a full return on investment within 6 months through significantly reduced downtime.

Check below popular items for more information in PLC-Pioneer.